Otto Simon Thermal Industries

OSTI

OSTI has a long history in supporting our clients with the routine and ongoing operation and maintenance of thermal assets. We have successfully supported our term clients in achieving safe and routine maintenance schedules and extending the working life of their assets. OSTI has the capability and experience to provide the following services in this field:

- Routine survey and condition monitoring of refractory and associated mechanical structures.

- On line hot inspections including endoscopy.

- Production of maintenance regimes and providing appropriate labour and plant to execute projects.

- Production of specifications, scopes of work and enquiry packages for discreet scopes of work.

- Compliance studies to assess compliance to latest regulations and legislation.

- Environmental assessments.

- Process and operational safety studies.

- SIL assessment and testing.

OSTI can support in the monitoring and assessment of thermal assets during production. We have the tools and experience to provide a range of services in detailing the operational performance of an asset including:

- Thermal imaging and inspections (External)

- Endoscopic investigations (Internal)

- Environmental emission monitoring

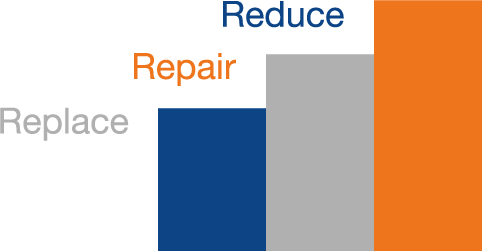

OSTI has the capability to support clients using specialist techniques to enact repairs without bringing their valuable asset fully out of service. OSTI can plan and manage work to fit within operational windows in order to minimise any disruption to production. Our capabilities include:

- Hot ceramic (Silica) welding of cracked joints, skew lines and damaged areas, OSTI can provide a range of ceramic welding powder mixes to match existing refractory.

- Overcoating and boxing of hot spots.

- Removal and replacement of mechanical door seals.

- Planning and managing “hot idles”, enacting repairs without having to cool down the asset.

- Cutting of access ports in live asset to undertake small repair works.

Where operations allow for a planned or emergency asset cool-down OSTI can support clients with repair works from patch repairs to full rebuilds. Our capabilities include:

- Demotion and rebuild of refractory brick structures, including specialist shapes such as crowns, arches, burner corbels and rotary kilns.

- Surface preparation including anchors, hex mesh and pannelisation.

- Shotcrete and/or gunnite application.

- Cold Welding of small or difficult to reach trouble spots.

- Duct, furnace or crucibal relining with castable refractories.

OSTI can support all Project Management activities, from FEED studies including CAPEX and OPEX estimates to delivering large scale and technically challenging projects. OSTI has a proven track record as operating as Principal Designer and Principal Contractor under the CDM regulations (2015) and can support our clients in ensuring robust schedule, cost and quality control.

For more information on the full range of our design and project management capability please visit the Otto Simon Project Delivery page.

OSTI can support our clients in the technical specification, design and procurement of materials, equipment and packages for our clients thermal assets and associated plant. From process reviews through to full plant redesign OSTI can support all asset improvement projects. We have strong relationships with many technology providers and original equipment providers.

Through our supply chains OSTI can procure either directly or for and on behalf of our clients to best suit their needs. OSTI have previously undertaken the procurement of the following and much more:

- Refractory materials

- Mechanical supports and stays

- Oven doors and door jambs

- Heat exchangers

- Flare and vent stacks

- Large bore gas ductwork

- Gas cleaning and processing

- Skidded units (Reversal systems, hydrogen mixing skids)

- Valves (including manual and automatic, control, relief)

- Pumps and fluid control devices

- Electrical management systems (MCC’s, switch-systems, transformers)

Cement & Lime

Glass

Iron

Coke

Metal

Waste

Petrochemical

Chemical