Stronger Together

Otto Simon Ltd • December 8, 2014

Allies for Coke Making Excellence: Otto Simon acquires John M Henderson.

Otto Simon is delighted to announce that we have formally executed an Asset Purchase Agreement with John M Henderson & Co Limited, acting through its joint Administrators, Blair Nimmo and Geoff Jacobs of KPMG LLP, to successfully acquire the John M Henderson Coke Oven Machinery technology and expertise.

The acquisition brings together two names with long and distinguished histories dating back to the 19th century and a common vision of providing outstanding competence in the coke and steel sectors.

The John M Henderson technology, developed and perfected during more than sixty years of R&D innovation, is the world’s leading coke oven machinery technology with more than 200 successful machinery projects completed worldwide.

The John M Henderson brand will be retained together with a core team of machine experts and continue its long established presence in the coke making industry, providing best available coke oven machinery solutions to coke plants worldwide. The business will operate as an independent entity out of newly established offices in Forfar, Scotland.

Sister company Otto Simon Limited is a leading process led consultancy and project delivery organisation with a proud heritage and distinguished track record of success and expertise in the coke and steel sectors in its own right.

The combined skills, knowledge and experience of Otto Simon and John M Henderson will be leveraged to create a strong presence in the UK coke and steel making sectors, increasing the range and depth of service offering to cover all aspects of coke production from by–products and coke ovens to state-of-the-art coke oven machinery.

Commenting on the acquisition, Steve Haywood, the Chairman of Otto Simon Holdings, said: “I am extremely pleased that we have been able to acquire the John M Henderson technology and key staff. The synergies with Otto Simon Ltd in the UK and our proud association with Thyssen Krupp Industrial Solutions will enable JMH to be even more successful in the future and ensure that the latest technology for oven machines is always available to coke plants around the world.”

Blair Nimmo, head of restructuring for KPMG in Scotland and Joint Administrator, said: “I am delighted that we have managed to sell a key part of the business which has not only generated employment in the Angus region but also helps maximise opportunities for businesses throughout the United Kingdom. We wish Otto Simon every success for the future”.

Gary McCombie, Managing Director of John M Henderson Machines Ltd, said: “John M Henderson and Otto Simon are an exceptionally good match, with aligned strategic visions and a shared culture of providing engineering excellence, innovation and customer success in the coke and steel sectors. We are stronger together than we were as individual entities.”

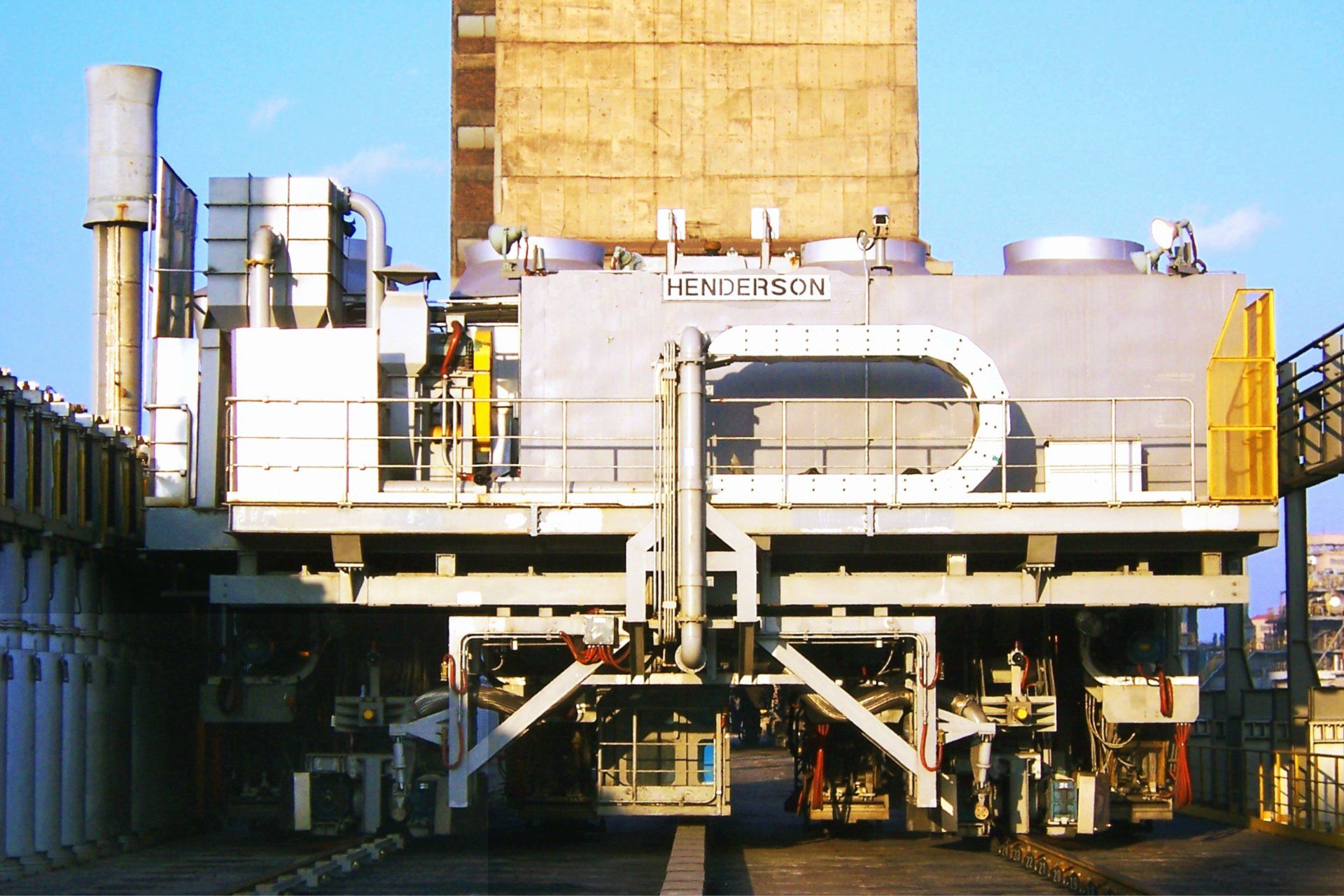

About the John M Henderson Technology

The John M Henderson coke oven machines are widely recognized as “Best Available Technology”, because of their pollution control performance, maximum reliability, ease of maintenance and minimum operating costs.

With near 150 years of expertise in Engineering Design, Manufacturing and Installation, and a proud track record of more than 200 Coke Oven Machines successfully completed worldwide, John M Henderson technology delivers a powerful combination of Fully Manless Operation with Total Environmental Control, each machine tailored to meet customer’s specific configuration and requirements.

For more information, visit the John M Henderson Webpage.

Back to Blog

Show More

Show More

Recent Blog Posts

At Otto Simon, we’ve been carefully reviewing the UK’s Modern Industrial Strategy 2025 to understand the potential impact on the sectors we serve — and, more importantly, how this may affect our clients and partners. While we highly recommend reviewing the full strategy yourself at The UK's Modern Industrial Strategy 2025 - GOV.UK , here are the main take-away points from Otto Simon’s perspective: Chemicals Sector The strategy outlines several important proposals aimed at supporting the UK’s chemicals and manufacturing industries. Key areas of focus include: Reducing Industrial Electricity Costs – The government aims to expedite grid connections for new power generators and increase investment in green energy. In addition, continued support for the Energy-Intensive Industries Compensation Scheme is planned. For many Otto Simon clients who rely on high volumes of energy for their operations, these measures could significantly lower overheads. Historically, UK industry has faced much higher electricity costs than many international competitors — so this change should improve both competitiveness and investment potential. Easing the Regulatory Burden – Otto Simon supports clients in meeting both legal and moral obligations around safety and compliance. While regulation remains essential for managing risk in high-hazard environments, unnecessary administrative burdens often create inefficiencies. Although further detail is awaited, we will continue to monitor developments and help our clients interpret and implement any changes to legislation or industry standards. Improving Infrastructure and Planning Processes – The strategy includes proposals to reduce planning barriers and invest in key infrastructure. Improved logistics and access to essential inputs can enhance operational reliability and help maintain competitiveness across the chemicals sector. Hydrogen Sector The government has reaffirmed its commitment to clean energy — including hydrogen — by doubling investment in the sector. This aims to strengthen the UK’s position as an early leader in the hydrogen economy, particularly in technologies such as electrolysers and engineering services. The transition from natural gas to hydrogen represents a key component of the UK’s future energy strategy, with significant potential for decarbonising industrial processes. Otto Simon continues to support clients seeking to integrate hydrogen as a viable fuel source and remains actively involved in the delivery of practical, large-scale hydrogen solutions across heavy industry. This includes supporting the development of projects under the UK’s Hydrogen Allocation Rounds (HAR1 and HAR2), which aim to bring low-carbon hydrogen production to commercial scale. Industrial Biotechnology Sector Otto Simon has a strong track record in supporting innovative companies working in fermentation and biotechnologies. While the 2025 strategy does not explicitly target industrial biotechnology, adjacent sectors — such as pharmaceuticals and clean energy — are likely to benefit from broader support measures. We acknowledge that the UK/US trade agreement may impact the competitiveness of certain bio-based fuels such as bioethanol, but the UK remains home to a vibrant innovation ecosystem. Otto Simon stands ready to assist these organisations in developing technologies that support the UK's sustainable future ambitions. Emergent Technology Sector The strategy makes clear the government’s ambition to support the entrepreneurial ecosystem — a key segment of Otto Simon’s Emergent Technology client base. Key initiatives include: Driving Innovation – The government is looking to incentivise collaboration between academia and industry, fostering innovation-led growth across the UK. With many ground-breaking technologies historically relocating abroad due to high costs, the government’s goal is to retain and nurture these businesses within the UK economy. Improving Access to Finance – Through grants, loans, and tax relief schemes, the government intends to support early-stage and high-growth businesses. Expanding access to funding can help these companies commercialise innovations and scale operations. Otto Simon continues to support emergent technology enterprises — offering expertise from concept design through to deployment — ensuring engineering and process challenges don’t slow down innovation. Conclusion The 2025 Industrial Strategy signals a renewed focus on long-term government support for UK industry — particularly in innovation, clean energy, and manufacturing. Otto Simon will continue to track these developments closely, working alongside our clients and partners to ensure they remain informed, prepared, and positioned to benefit from the evolving industrial landscape.

Otto Simon recently attended the Hydrogen Energy Association (HEA) annual conference in Westminster, London, a key event for the hydrogen industry. The conference featured a keynote speech by Sarah Jones, UK Government Minister of State for Industry and Net Zero , highlighting the government's commitment to this crucial sector. Our team had the invaluable opportunity to hear directly from industry-leading hydrogen experts , gaining first-hand insights into the latest policies and government funding initiatives. This direct access to information is vital for staying at the forefront of hydrogen advancements. Congratulations to Clive Mansfield and Clare Dunkerley from our team, who actively participated in the networking sessions, engaging in discussions about hydrogen and safety —a critical aspect of our work. They also gathered useful information that will directly benefit our ongoing hydrogen projects.

Here at Otto Simon, we're committed to staying at the forefront of safety and compliance in Process Plant projects. That's why two of our seasoned principal engineers, Mike Wray and Mike Westerman, recently attended a crucial refresher course on machinery regulations at the HSE Science and Research Centre. In the world of Process Plant projects, it's common to encounter machinery assemblies where vendors don't provide a declaration of conformity. With the recent publication of the new EU Machinery Regulation 2023/1230/EU, it's more important than ever to be on top of the latest guidelines. This ensures we can continue to offer our UK-based clients the best advice on their responsibilities and how to apply conformity assessments when machinery risks are present. This applies to both new equipment and the repurposing of existing machinery. Considering there are over 800 standards related to machinery design, our approach is meticulous. We utilise a thorough hazard identification process to carefully evaluate risks and implement best practice safety mitigations in all our designs. This proactive approach helps us ensure the highest level of safety for your projects. Please get in touch for assistance.