Standards Development: PAS 4445:2025 for Hydrogen-Fired Equipment

Standards Development: PAS 4445:2025 for Hydrogen-Fired Equipment

The future of energy is undeniably leaning towards hydrogen, a clean and versatile fuel poised to revolutionise industrial and commercial operations, which is required to take place within 25 years to meet the country’s net zero targets.

Today, we are proud to celebrate both our contribution to, and the publication of, Publicly Available Specification (PAS) 4445:2025, hydrogen-fired equipment. The publication is a significant step forward in ensuring the safe and effective integration of hydrogen-fired equipment into industrial and commercial applications. This standard will play a crucial role in fostering confidence and driving innovation.

Otto Simon’s Support:

In early 2024, BSI invited Otto Simon Ltd. to provide expert technical representation on the Steering Group for the development of the fifth publication in the PAS series concerning hydrogen appliance/equipment fuel gas. This initiative builds upon the four preceding publications, which focused on the transition to hydrogen as a replacement for natural gas within the UK's domestic and small business sectors.

The fifth publication, PAS 4445:2025, expands the scope to address the implementation of hydrogen in larger, more complex industrial applications, necessitating significant deviations from established domestic installation practices.

Mike Wray, Principal Mechanical Engineer at Otto Simon, joined the Steering Group, contributing alongside technical representatives from diverse industrial equipment suppliers, end-users, and the Department for Energy Security and Net Zero (DESNZ). Throughout the second half of 2024, the group convened to provide technical guidance and input into the publication's development. Mike Wray's expertise, gained from his involvement in the Keele University HyDeploy project plus numerous industrial fuel switching trials as part of the HyNet North West UK Hydrogen network and CCUS projects, proved to be invaluable.

Under the proficient leadership of Beverley Goodchild (BSI), who effectively managed group discussions and maintained focus on achieving a successful outcome, the Steering Group finalized PAS 4445:2025, "Hydrogen fired equipment for use in industrial and commercial (non-domestic) settings – Code of Practice." This publication, released in late March 2025, aims to establish a robust technical framework for fuel gas users and equipment suppliers transitioning to low or zero-carbon fuel utilisation in their operational processes and system designs.

Why PAS 4445:2025 is Significant:

The use of hydrogen, while promising, requires meticulous handling and infrastructure. PAS 4445:2025 provides a comprehensive framework to:

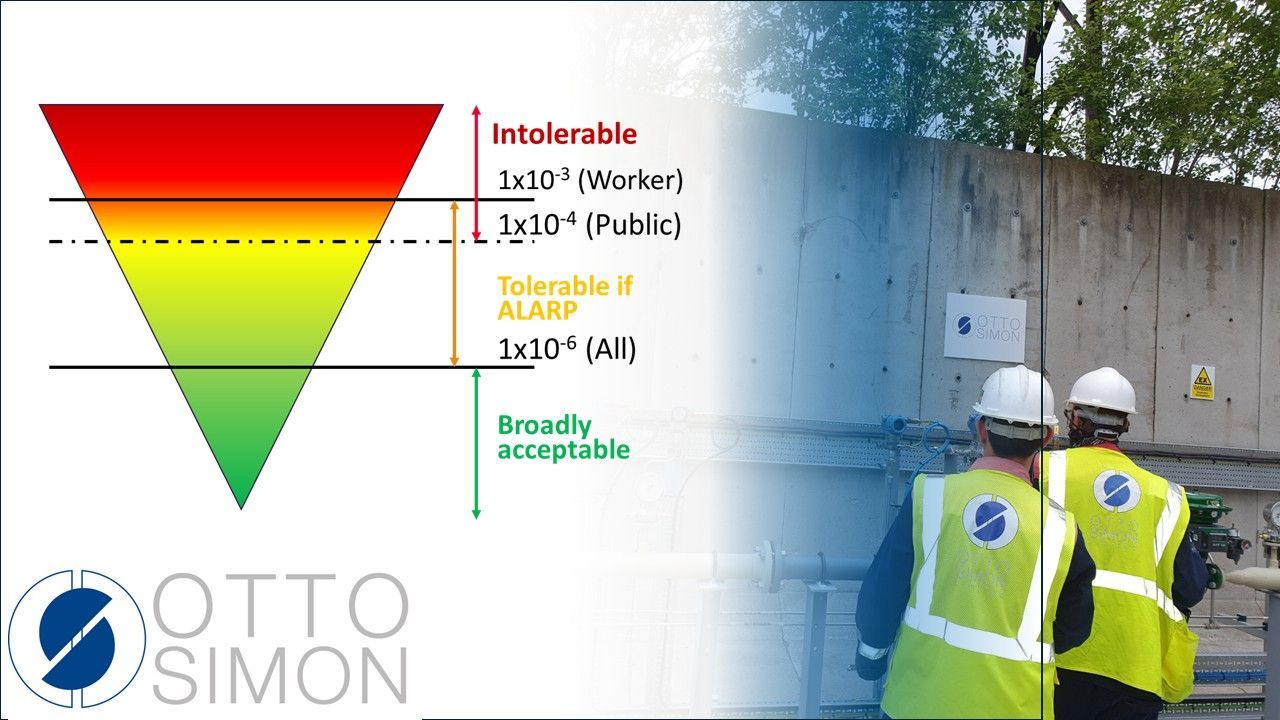

· Prioritise Safety: Establishing stringent safety protocols for the design, installation, operation, and maintenance of hydrogen-fired equipment.

· Optimise Efficiency: Promoting best practices to maximise the performance of hydrogen utilisation

· Minimise Risks: Addressing potential hazards associated with hydrogen storage, handling, and combustion.

· Standardise Practices: Providing clear and consistent guidelines for organisations across the hydrogen equipment value chain.

· Enable Industry Growth: Fostering confidence and accelerating the adoption of hydrogen technologies.

Who Will Benefit from PAS 4445:2025?

This PAS is vital for a wide range of stakeholders, including:

· Manufacturers of hydrogen-fired equipment.

· Industrial and commercial users of hydrogen technologies.

· Engineering and construction firms.

· Safety and regulatory bodies.

· Hydrogen infrastructure developers.

· Insurance providers.

By developing the guidelines in PAS 4445:2025, Otto Simon has further demonstrated its commitment to safety, its technical understanding and continuing contribution to the hydrogen economy.

Recent Blog Posts