Hy Deploy Project

Otto Simon Ltd • January 30, 2018

OSL is supporting a pioneering energy trial of blended hydrogen and natural gas

Reducing carbon emissions is a top priority for the UK; having committed to an 80% reduction by 2050. By blending hydrogen into the normal gas supply across the UK, 6m tons of carbon could be saved every year; that’s the equivalent of removing 2.5m cars from the road.

For more than a year a consortium of grid operators and technical experts have been working together to develop the technology to produce low-carbon hydrogen and blend it into the gas network. The project will conduct a year-long live trial of blended gas at Keele University; using the campus’ own private gas network to host the trial. As the largest campus in the UK, the university’s private network serves a mixture of residential and commercial buildings, providing an accurate representation of a small town.

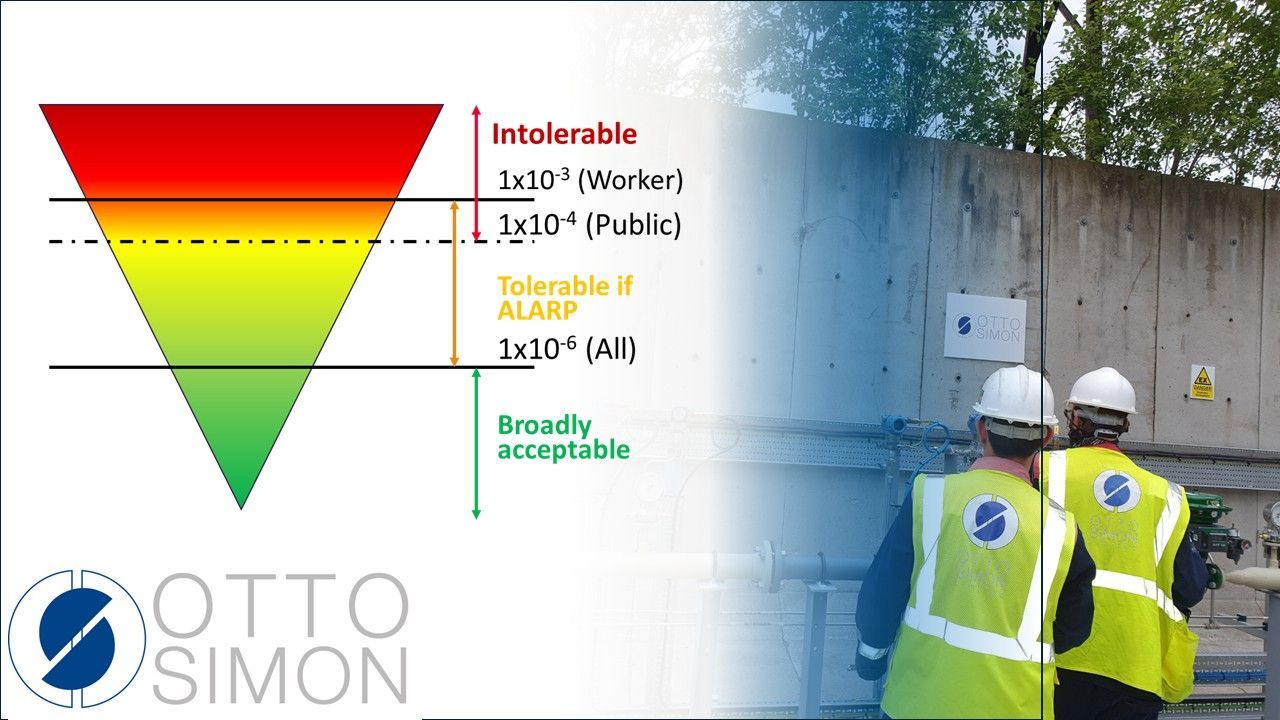

The project aims to establish and demonstrate the level of hydrogen that can be safely blended with natural gas for use across the UK, and will provide practical evidence that the hydrogen blended gas can be delivered without any impact to customers. As the existing national gas grid was originally designed for Hydrogen rich gas before the North Sea boom provided a flood of cheap natural gas to burn instead, it is expected that few appliances would need to be replaced to safely work with the hydrogen blend.

HyDeploy is a consortium between Cadent Gas Limited, Northern Gas Networks, Keele University, Health & Safety Laboratory, ITM Power and Progressive Energy, the HyDeploy project is also supported by specialist gas safety testing specialists Kiwa, industry research experts Dave Lander, with technical consultancy provided by Otto Simon.

Read more about this exciting project on the HyDeploy website and in Otto Simon's project reference.

Back to Blog

Show More

Show More

Recent Blog Posts

Well, another year is winding down, and what a year it’s been! Here at Otto Simon, we decided to celebrate all the hard work and dedication of our fantastic team with an evening of festive fun, delicious food, and a touch of wanderlust! A huge, heartfelt thank you goes out to Anna for orchestrating what was a truly splendid Christmas gathering. From the atmospheric lighting to the perfectly planned tapas, Anna, you outdid yourself. Our merry band descended upon Trunk Lounge in Bramhall, and it was fantastic to see such a great turnout, proving that even after a busy year, we still love spending time together! Now, every good story has a new chapter, and for one of our own, that chapter involves packing a very large suitcase! We had the pleasure of raising a glass (or several!) to Chris and his partner Lydia, who are embarking on an incredible year-long adventure, travelling the globe, we are not jealous at all. From all of us at Otto Simon, we wish Chris and Lydia the very best of luck on their incredible journey. We are all sure looking forward to reliving your amazing memories with you upon your return. We would like to end the year with sincere thanks to our Clients, Partners and Staff for all their efforts over the past year and are looking forward to another busy and rewarding year in 2026. Here's to a wonderful Christmas break for everyone, and a prosperous, exciting New Year!

This year we celebrated our year of successes and lessons learnt at the Stanneylands, Wilmslow. Topics included how we have streamlined our, reducing business overheads and making our collaboration more efficient. Specific attention was paid to the successes of the projects we have delivered over the last year and the consolidation of the team into our new headquarters. Ferrostatics proudly shared their highest year of revenue and strong performance, with a promising year to follow. We have also reviewed key team changes, including the expansion of the engineering team and restructuring of our Sales team. We look ahead to 2026 with confidence, fresh focus and further passion to deliver leading engineering expertise and customer service!